top of page

Services Details

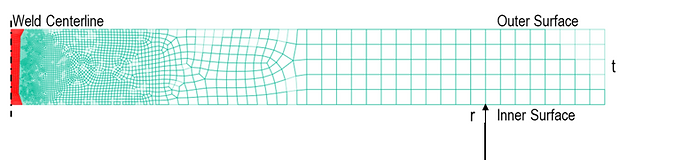

Finite Element Model Illustration

thickness t = 55mm (2”)

r/t Ratio = 1.6

73 passes

Stress contour comparison

without Phase Transformation

Comments on residual stress distribution in BS7910:2013 Appendix Q

BS7910 or API 579 on Pipe Girth Welding – Joint Preparation

-

Only Single-V is considered

-

No narrow groove and double V-shaped

4” and r/t=10

Validation Studies – Nozzle Welds 1

No phase change was considered

Validation Study – Pipe Girth NG Weld

Bouchard, P.J., “Validated Residual Stress Distribution for Stainless Steel Pipe Girth Weld Fracture Assessment,” International Journal of Pressure Vessels and Piping 84 (2007) 195-222

Parametric analysis matrix

Pipe girth welds, r/t = 2, 5, 10, 20, 100

1/4"

1/2"

1/4"

1"

2"

4"

10"

SV

X

X

X

X

X

X

X

DV

X

X

X

X

X

X

X

NG

X

X

X

X

X

bottom of page